Enhancing Durability and Comfort with the Mattress Comprehensive Performance Tester

Dec 12, 2023

Enhancing Durability and Comfort with the Mattress Comprehensive Performance Tester

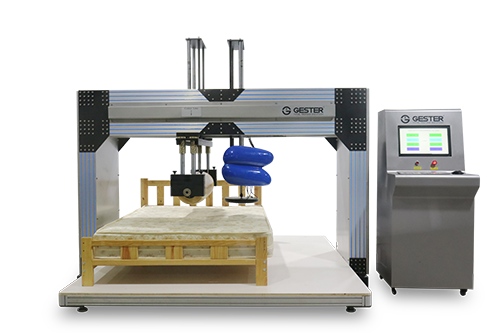

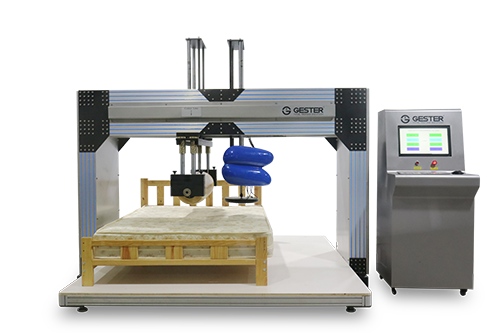

The important factor influencing a restful night's sleep and overall well-being is the quality and performance of mattresses. Manufacturers employ sophisticated testing techniques and equipment to guarantee the durability and comfort of mattresses. Among these tools is the Mattress Comprehensive Performance Tester, a comprehensive machine crafted to elevate the durability and comfort of mattresses through thorough performance testing. This article delves into the ways in which the Mattress Testing Machine improves the quality of mattresses, ensuring they conform to rigorous industry standards.

1. Height Loss Test:

The Mattress Comprehensive Performance Testing Machine incorporates a height loss test function, which measures the change in height of a test unit caused by the durability test. This test assesses the ability of a mattress to maintain its original form and structure over time. By subjecting the mattress to repeated loading and movement, the Mattress Testing Machine simulates the long-term use conditions, helping manufacturers identify potential weaknesses or deformations that may affect the comfort and performance of the mattress.

2. Durability Test:

The durability test is a crucial procedure to evaluate the change in properties of the mattress caused by repeated loading. The Professional Mattress Durability Tester follows internationally recognized standards such as EN 1957, EN 1725, QB/T 1952.2, or ASTM F1566, ensuring that the test accurately replicates real-world usage scenarios. By subjecting the mattress to simulated wear and tear, the machine allows manufacturers to assess the strength and structural integrity of the mattress, identifying any potential issues that may arise over time.

3. Hardness Value & Firmness Rating Test:

To determine the firmness and hardness characteristics of a mattress, the Mattress Testing Equipment incorporates load/deflection measurements. By pressing a load pad into the test unit and measuring the associated values of indentation and force simultaneously, the machine accurately determines the hardness value. This objective measurement provides valuable data for manufacturers to understand the firmness level of the mattress. Additionally, the firmness rating, based on empirical studies, expresses the subjective assessment of individuals. Combining both objective and subjective evaluations, manufacturers can fine-tune the design and materials of the mattress to meet the desired comfort levels.

4. Bed Edge Durability Test:

The bed edge durability test is another essential function of the ASTM F1566 Mattress Testing Machine . By applying a force of 1000N for 5000 cycles using an edge loading pad at the bed edge test point, the machine evaluates the mattress's ability to withstand pressure and maintain its shape. This test is particularly important as the edges of the mattress often experience the most stress and strain during use. By measuring the height loss resulting from the test, manufacturers can ensure that the mattress retains its shape and support along the edges, enhancing the overall durability and comfort.

The important tool known as the Mattress Testing Machine for plays a pivotal role in substantially elevating both the durability and comfort of mattresses. Through meticulous measurements and strict adherence to industry benchmarks, the Mattress Durability Comprehensive Tester plays a vital role in guaranteeing that mattresses not only meet but exceed consumer expectations. It achieves this by delivering exceptional durability and ensuring unparalleled comfort, thus contributing to an optimal sleep experience.