What Does a Drop Test Entail for Packaging Materials?

Aug 23, 2023

What Does a Drop Test Entail for Packaging Materials?

Introduction

In the realm of safeguarding products during their journey, packaging plays a pivotal role. However, the true assessment of packaging's efficacy occurs when packaged goods undergo a variety of stresses and impacts. One pivotal evaluation technique in this domain is the Drop Test, a procedure aimed at replicating the potential drops and tumbles that a package could encounter during handling, shipping, or storage. This piece delves into the importance of the Drop Test concerning packaging materials, its applications, and the equipment employed for testing.

Comprehending the Drop Test

The controlled free fall experiment, known as the drop test, is designed to mirror real-life scenarios where packaged items may be accidentally dropped or subjected to falls. The objective is to gauge the packaging material's ability to withstand the impact without harming the enclosed product. This evaluation is of utmost significance as it aids manufacturers in pinpointing vulnerabilities in their packaging designs and effecting necessary enhancements before the products reach consumers.

Equipment for Package Drop Testing

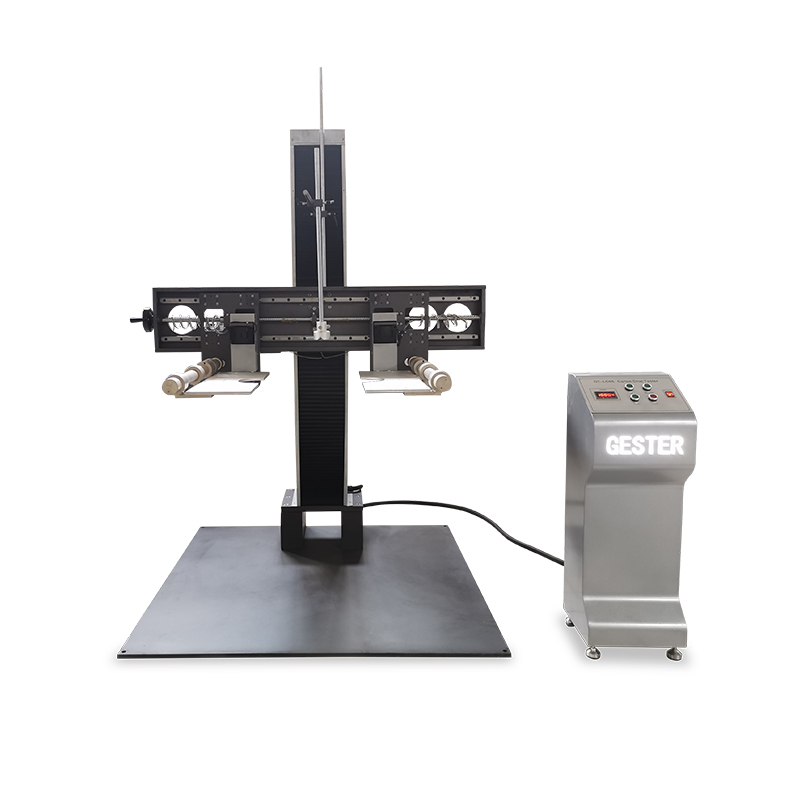

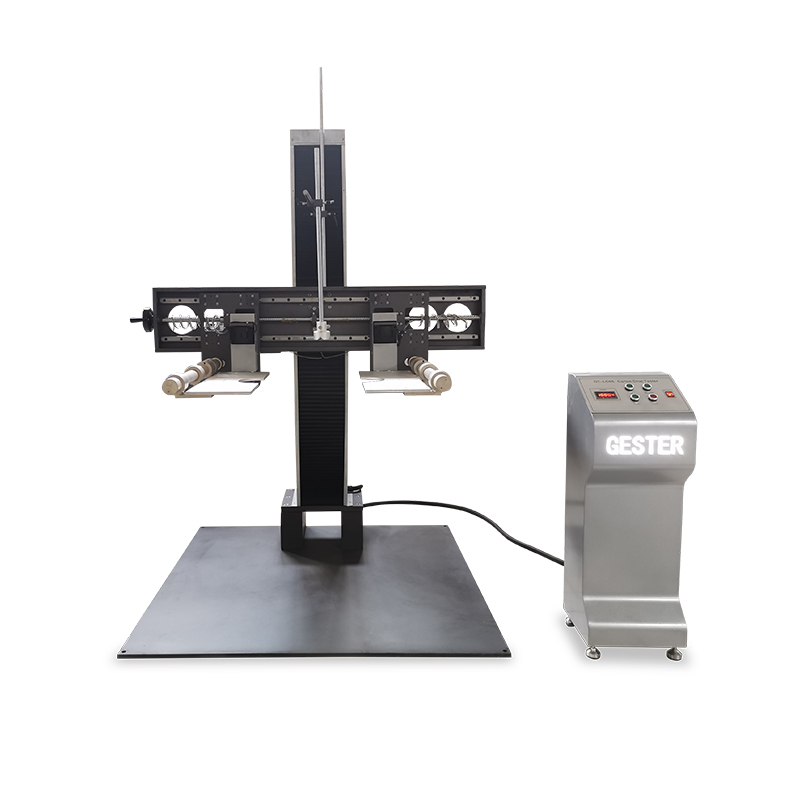

The process of conducting drop tests on packaging hinges on specialized apparatus, such as the GT-LC05-2 Double Wings Drop & Falling Tester. This apparatus employs a dual-column configuration combined with spring-based cushioning to provide a controlled dropping environment. The addition of a height measurement scale further refines precision, guaranteeing dependable outcomes. Noteworthy is the apparatus's capacity to emulate drops from diverse angles, edges, and surfaces, facilitating a comprehensive assessment of diverse packaging types.

Applications

The GT-LC05-2 Double Wings Drop & Falling Tester serves as a pivotal instrument in the realm of drop testing. Amid the movement and conveyance of products, unforeseen drops can transpire, potentially resulting in internal impairment. This drop test packaging apparatus aims to proactively mitigate such harm by emulating varied scenarios of objects falling. Through subjecting the packaging to regulated drops, manufacturers can discern optimal solutions to curtail potential losses during transit.

Standards and Directives

To ensure uniformity and dependability in drop testing protocols, various benchmarks have been established. These include ISO 2248, JIS Z0202, GB/T4857.5, and ISTA. These norms for package drop testing furnish comprehensive guidelines regarding the conduction of drop tests, the quantifiable parameters, and the benchmarks for evaluating outcomes. Adhering to these criteria upholds coherence and precision within the industry.

Conclusion

Within the universe of product packaging, the free fall drop test stands as a pivotal assessment technique that emulates the real obstacles that packages confront during transit. With technological headway, tools like the GT-LC05-2 Double Wings Drop & Falling Tester have surfaced, supporting manufacturers in more extensively evaluating packaging materials. Staying aligned with established benchmarks ensures uniformity and dependability, while the utilization of specialized apparatus ensures precise and replicable testing. Ultimately, drop testing within the packaging sphere contributes to the development of packaging materials that adeptly shield products on their expedition from producer to consumer.